Product Feature

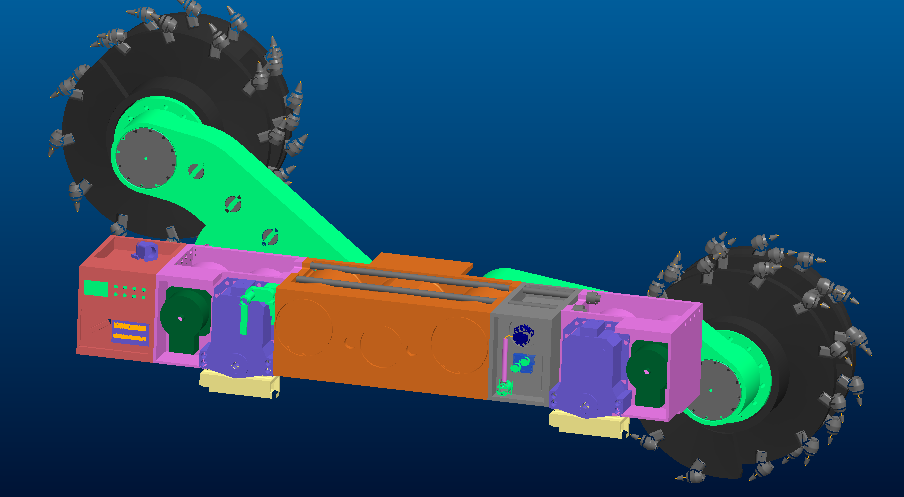

*SWS300-NW shearer is hydraulic haulage shortwall dual drum shearer with single motor horizontal layout. The total installed power is 300kW, it can be matched with single prop, articulated roof beam and suspension movable support, and it can be used in shortwall fully mechanized mining and fully mechanized caving face. This coal shearer can do rotary cutting feed at the machine head and tail according to the working surface equipment and roadway structure.

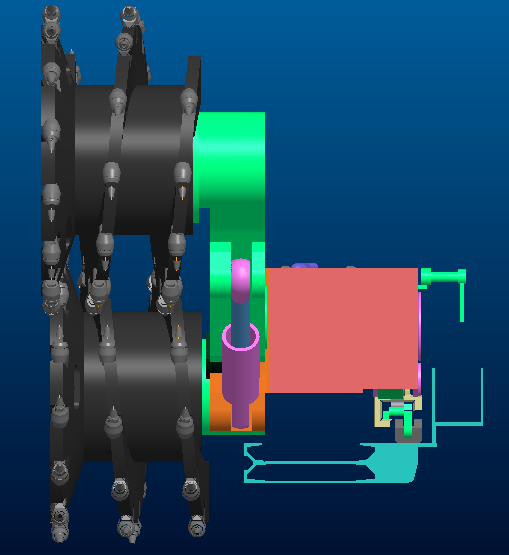

*The whole machine is composed of main body, left and right cutting part, electric cabinet, walking box, hydraulic system, supporting leg, height-adjustment oil cylinder, other auxiliary devices, parts, oil pipes, water pipes, cables, etc.

*One side of the height-adjustment oil cylinder is fixed on the main body, and the other side is fixed on the arm of the cutting part. The stretching of height-adjustment oil cylinder makes it possible that cutting arm of the cutting part can be adjusted, which is suitable for the change of the mining height. The drum is arranged at the output end of the cutting part to complete the coal loading and the coal falling operation.

*Travel unit is driven by a main motor to drive the left and right travel motor, the motor drives the walking wheel and pin engagement after deceleration to complete left and right traction of the machine.

*The supporting component is fixed at the bottom of the coal shearer main body through the positioning pin. The supporting component and the guide sliding shoes on the travel unit bear the weight of the whole machine together.

Working Principle

The shearer is supported by the two groups of supporting components on the coal wall side and the two guide sliding shoes on the operating side respectively. The walking wheel in the walking box and conveyor pin rail is engaged, when the walking wheel rotates, the shearer will do forward or reverse traction walk on the working face conveyor, at the same time main motor drives main pump, left and right cutting unit, the cutting unit drives rotation of drum to complete coal loading and coal falling operation.

Technical Features

*The whole machine adopts the structure of short-wall, hydraulic haulage double-drum which is suitable for the short wall working face, and can realize the full mining height at one time.

*The width of the machine is 100mm, which can effectively shorten the distance between the top and the bottom of the coal mining face, and is suitable for the working face whose roof is unstable or moderately stable.

*The length of the whole machine is 4200mm, especially suitable for short-wall working face.

*The design of the transmission system of the whole machine adopts the company's patented design full roller bearing design, which saves space for the overall design and enhances the reliability.

*In order to be able to adapt to frequent surface moving operations, the machine parts are designed and manufactured based on the principle of easy dis-assembly and the weight of all individual parts shall not exceed 1.5 tons.

*A safety clutch mechanism and a shear pin are arranged in the transmission system of the cutting part, in order to make sure the transmission parts will not be damaged when the impact is overloaded and provide convenience for maintenance.

*The whole machine body adopts modular design, each module unit adopts dry butt joint.

*Output of the end of the cutting part adopts 4 planetary reducer, which is safe and reliable, minimizes the size of the upper drive parts.

Technical Parameters

|

No. |

Description |

Unit |

Value |

|

1 |

Model |

SWS300-NW |

|

|

2 |

Mining Height |

m |

1.4~2.2 |

|

3 |

Dip Angle |

° |

≤20 |

|

4 |

Strike Angle |

° |

±8 |

|

5 |

Hardness |

f≤4 |

|

|

6 |

Motor Power |

kw |

300 |

|

7 |

Voltage |

V |

1000 |

|

8 |

Machine Height |

mm |

1050 |

|

9 |

Swing Arm Rotation Angle |

° |

-7.95 +36.4 |

|

10 |

Length of Swing Arm |

mm |

1517 |

|

11 |

Coal Passing Height |

mm |

319 |

|

12 |

Undercutting Depth |

mm |

148 |

|

13 |

Drum Diameter |

mm |

Φ1250 |

|

14 |

Web Depth |

mm |

630 |

|

15 |

Drum Width |

mm |

730 |

|

16 |

Drum Rotation Speed |

rpm |

43 |

|

17 |

Control Mode |

Remote control, centralized control, end station |

|

|

18 |

Speed Regulating System |

Hydraulic stepless control |

|

|

19 |

Haulage Mode |

Gear - pin rail type chainless haulage |

|

|

20 |

Pin Row Space |

mm |

125 |

|

21 |

Haulage Speed |

m/min |

0~5.9 |

|

22 |

Haulage Force |

kn |

220 |

|

23 |

Cooling Mode |

Water cooling and recycling |

|

|

24 |

Model of Water Tube |

KJR19-150/L |

|

|

25 |

Weight |

t |

~15 |