Introduction of AFC

SGZ630/110 AFC is a kind of inboard double chain armored face conveyor , which could realize mechanization mining with configuration of shearer and semi-shield roof support. This kind of flexional AFC could not only adapt the convex concave bending working condition, but also could curve and bend itself along with the advancement of working face, and without manual disassembly. What’s more, the AFC could be as the guide rail of shearer, and makes the shearer cling to the mine wall, which could narrow the unsupported roof span and be good for roof management.

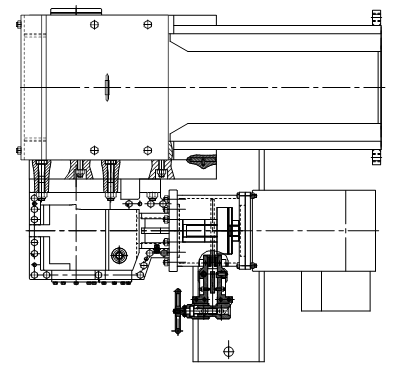

As forepart AFC, the middle pan uses high quality M shape box iron and high wear-resistance middle plate, with very firm strength and light weight. It’s driven by double motor, with vertical layout, the total motor power is 110kw, supply voltage is 480V, and is made up of head(tail) drive part, middle pan, scraper chain and tail.

Features of SGZ630/110 AFC

1)The weight of the whole machine is minimized under the premise of ensuring the reliability when the machine is designed and manufactured, and it is suitable for the frequent overall migration of the short wall surface equipment.

2)The transmission part of the head consists of two parts: the power part and the machine head.Based on the head, the power unit (composed of reducer and motor) can be linked as a whole to the left or right side of the machine head according to the requirements of different working faces. The way of power transmission is from motor torque to the input shaft of the speed reducer, after the deceleration done by the reducer, external key of output shaft is engaged with internal key of head sprocket shaft, the scraper chain will be pulled by the sprocket.

3)The head frame is welded steel structure, the reducer, sprocket assembly and other transmission parts are fixed on it, the structure is rigid, symmetrical structure can meet the requirements of different working faces.

4)The reducer is from domestic well-known brand Jiangsu Boneng Transmission Co., Ltd, the quality is guaranteed.

5)The machine tail is mainly composed of the tail drum and tail frame. The tail drum is installed on the machine tail frame, there are sprockets on the drum which play a role of guidance and fixing to the chain. This way is used for keeping the chain in the center line and ensuring stable operation of the chain.

6)Scraper chain is the main working mechanism of scraper conveyor, it must bear large static load and dynamic load in the working process, plus the friction with the chute, therefore, it is required high wear resistance, toughness and strength. So the scraper conveyor chain is made of alloy steel, and heat treatment is required after welding to meet the requirements of strength, toughness, wear resistance and other performance.

7)Middle trough is the body of the scraper conveyor, high strength, rigidity and high wear resistance are required, because the body will be used as the guide rail of the shearer.

Technical Parameters

|

No. |

Description |

Unit |

Value |

|

1 |

Length |

m |

100 |

|

2 |

Capacity |

t/h |

200 |

|

3 |

Chain Speed |

m/s |

0.8 |

|

4 |

Chain Type |

Inboard Double Chain |

|

|

5 |

Chain Type |

Flat chain 22×86 |

|

|

4 |

Middle Pan |

mm |

1500×590×205 |

|

5 |

Middle Pan Connection Mode |

Dumbell pin connection |

|

|

6 |

Middle Pan Structure |

Standard Steel |

|

|

7 |

Horizontal Curvature |

° |

±1 |

|

8 |

Vertical Curvature |

° |

±3 |

|

9 |

Motor Power |

kw |

2×75 |

|

10 |

Frequency |

Hz |

60 |

|

11 |

Motor Layout |

Two end symmetrical arrangement |

|

|

12 |

Pin pitch |

mm |

125 |

|

13 |

Weight |

t |

85 |