When mining academic communities, mining engineers and most of Chinese equipment factories are still talking about the possibility of continuous longwall mining system technology and equipment for metallic mines, we have successfully applied continuous shortwall working face mining system in Boleo Copper Mine, Baja California Sur, Mexico, in March 2019.

We’re one of the second companies who optimized the underground longwall coal mining technology and applied it for underground hard-rock mining practice, surely, this is bellwether in Chinese mining industry.

[Caterpillar is the first company in the world who applied longwall system to underground hard-rock mining in 2016.]

Metallic / non-metallic mines continuous longwall mining system is a complete set of full mechanized longwall mining system, which is specially used for layer cladding metallic/non-metallic deposit mining with medium / low hardness, such as some kind copper mine, phosphate mine, bauxite mine and etc. This system took reference from well-developed longwall coal mining technology, and also found a new path besides coal mining experience, according to special features of metallic / non-metallic mines, we made a series of optimization and development, to improve the stability and efficiency of the mining system, and flexibility of mining technology and method.

Compared with typically traditional drill and blasting mining method in major layer cladding metallic / non-metallic mines, the continuous longwall / shortwall mining system has following advantages:

1. This system can realize continuous mining and continuous conveying along with the seam simultaneously, which can improve the cutting, loading and conveying capacity greatly;

2. By using free-fall method to manage the goaf roof, there’s no need to reserve pillar for roof support, thus increased the mining efficiency. On the other hand, the production and operation cost is reduced.

3. The mining activities are completed by Cutting Machine (shearer), because it’s driven by motor power, lower cost compared with blasting, and no exhaust gas emission, which can decrease the risk for health and safety.

The continuous longwall / shortwall mining system consists of three sub-system: working face mining system, working face ore conveying system and working face roof support system, which can meet the requirement of cutting, loading, conveying and supporting at same time.

* Working Face Mining System

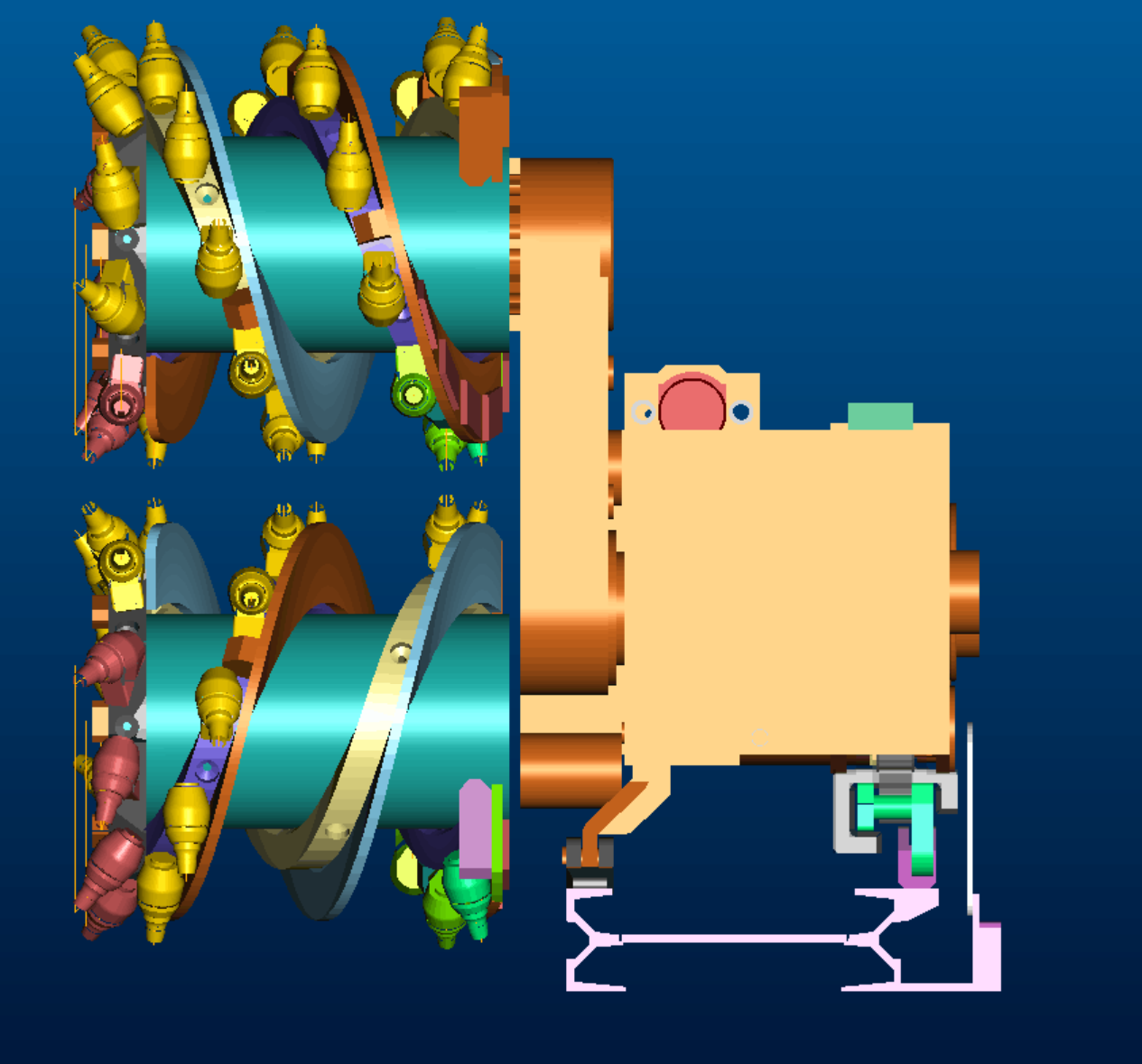

The working face mining system is crucial part of whole system, which is made up of traction unit, cutting unit, hydraulic unit, lubrication & cooling unit and main machine body. We flexibly customize and design the drum type(single drum or dual drums), drum size, swing arm type and etc. according to different ore body, ore properties, working face length and other conditions. The mining picks are made from high-strength alloy, and are arranged in best angle to cut ore, also the cutting speed and momentum are optimized to decrease the negative influence of abrasion and high temperature, thus to reduce the cost consumption of energy and spare parts replacement.

Moreover, it includes many modules to control, monitor and protect the mining system.

The Cutting Machine is controlled by 10m visible remote controller, which can help Cutting Machine driver to make suitable decision for speeding up and speeding down according to underground working face situation, thus to effectively avoid shutting down caused by varying ore seams condition, more importantly, the driver’s safety is guaranteed.

Mining Picks

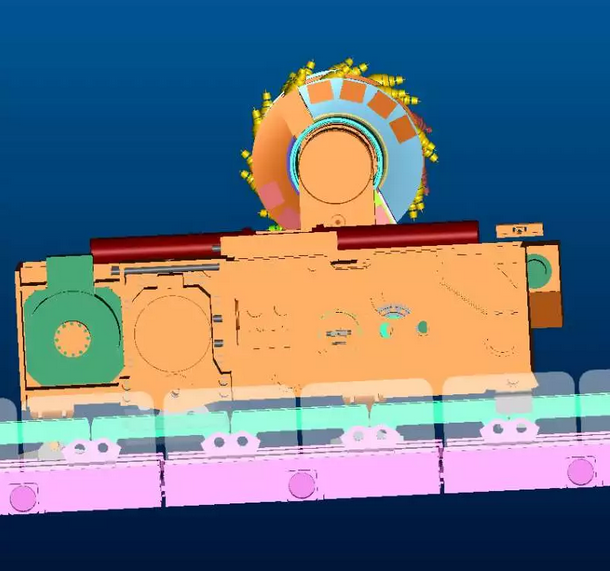

3D Design - Single Drum

3D Design - Dual Drum

* Working Face Conveying System

The conveying system is a Face Chain Conveyor (also called Armoured Face Conveyor or Scraper Conveyor), it can convey ore material and provide moving rail for Cutting Machine. After the ore cutting by Cutting Machine, it falls into the Face Chain Conveyor, and is transited to Belt Conveyor and outside by Gate Chain Conveyor.

The stable operation of this system is important for whole mine continuous mining activities. Considering special geological features of metallic / non-metallic mines, we made some special design on Face Chain Conveyor and Gate Chain Conveyor. For example, choose right arrangement of chain (inboard or outboard) to avoid negative impact from sticky material adhered to chain; use suitable chain size (18*64, 22*86 or even bigger) and steel material to reduce abrasion and increase the lifetime; assemble cleaning device to decrease adhesion and low conveying efficiency.

* Working Face Roof Support System

The roof supporting system provides available operation space for working, and advancing along with working face mining activities, also builds safe room for personnel and equipment. According to mines geological condition, surrounding rock ore body property and investment budget, we can flexibly choose Hydraulic Support, Semi-shield Support, Combined Hydraulic Support and etc. Compared with traditional roof-and-pillar support or back stowing method, this kind of roof support system can increase the mining recovery rate on the condition of safety, and reduce support cost.

Support System in Boleo

Difference From longwall Coal Mining Method

The principle of this mining system is same as well-developed underground longwall coal mining method in coal mining field, they both focus on continuous mining, loading, conveying and supporting simultaneously in bedded vein, thus to improve the mining recovery rate, and cut metallic / non-metallic ore with coal mining efficiency.

Because of special metallogenic condition and different ore deposit type compared with coal, it’s not easy to achieve continuous working face mining in metallic / non-metallic mine. To supply the system successfully in Boleo Project, we made a lot of customized design. For example, to cope with the problem of conglomerate in floor, we designed three levels protection devices for mechanical transmission unit to prevent the cutting machine from damage caused by cutting the hard and big conglomerate; optimize the distance between cowl and spiral drum mining tips to improve loading efficiency; set inspection window every 7 middle pans to check and clean the adhered material in bottom panzers. Thanks to these customization, this system works well in Boleo with stable performance and high capacity.

The application of continuous longwall mining in metallic / non-metallic mines is creative action to use one well-developed and mature technology into another unexplored field. The system is proved to be reliable and technological innovation, and provides a different idea for metallic / non/metallic mines in particular situation.

We’re skilled in underground mining design and complete system equipment supply. We have rich customization experience in hard mining conditions especially for low coal seam, steeply inclined angle, top caving and gas utilization.