Features of Cantilever Roof Support

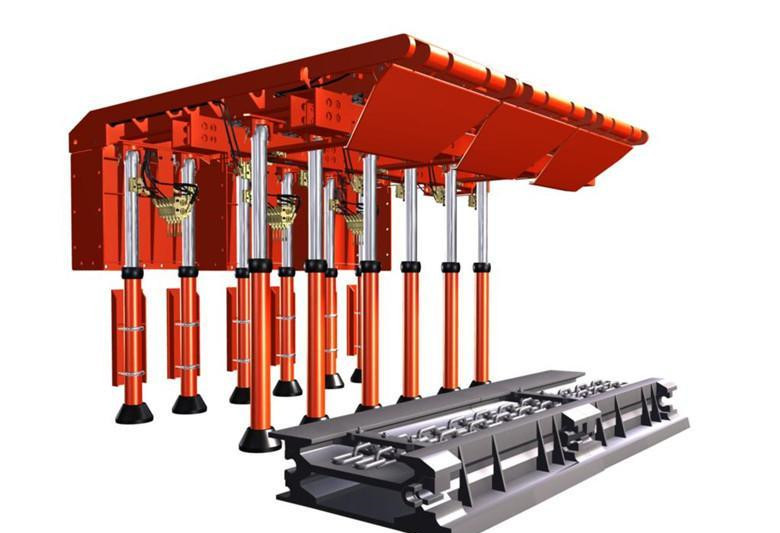

1.Large Supporting Area

Because the top beam section is integral box-type structure with dimension of 0.96m width and 2.6m length. The supporting area is more than 96%, which is same as fully mechanized longwall mining support, so the support can be used in broken roof working face. And there will be no roof leakage of high-grade working face and cantilever roof support working face.

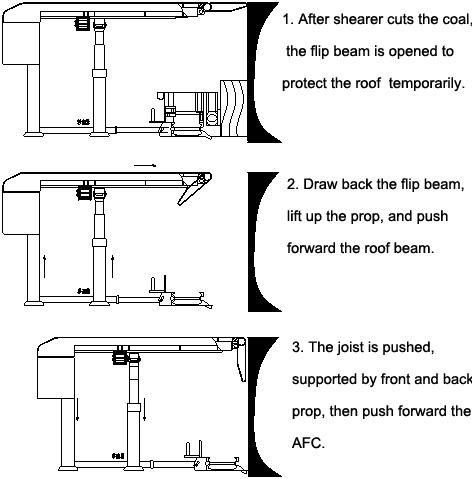

2. Fast Advancing Support Speed

The advancing velocity of working face is faster due to the simple moving method. And it can absolutely meet the speed requirement of mechanized mining working face.

It takes about 1~2 minutes to finish the whole 3 moving steps, which is equaled to the fully mechanized longwall mining.

3. Good Stability

Because full working face is linked as a whole through the beam system, it has good stability, working face can make sure the support will not fall. If there is head space above certain support or it is not supported well, overall moving beam and top beam suspension system make it will not fall, so the working face completely avoid the phenomenon of support’s skew and fall, security is greatly increased.

Operation Sequence of Cantilever Roof Support

Technical Parameters of Cantilever Roof Support

|

Item |

Unit |

Parameter |

Remark |

|

|

Basic Framework |

End Socket (Excessive) |

|||

|

Support Height |

mm |

1600-2400 |

||

|

Support Length |

mm |

2600 |

3200 |

|

|

Support Width |

mm |

960 |

||

|

Adjustable Beam Length |

mm |

800 |

Distance of travel 800 |

|

|

Center of Support |

mm |

1000 |

Support space 40mm |

|

|

Pillar Diameter |

mm |

Φ125 |

Bi-directional hydraulic prop |

|

|

Pillar Number |

pc |

4 |

||

|

Advancing Support Step Pitch |

mm |

800 |

||

|

Whole Frame Weight |

ton |

2.55 |

||

|

Supporting Intensity |

MPa |

0.52 |

||

|

Working Resistance |

Kn |

2000 |

||

|

Setting Load |

Kn |

1545 |

||

|

Column Shoes Diameter |

mm |

300×300 |

||

|

Control Mode |

Centralized control |

No liquid injection gun |

||

|

Advancing Support Mode |

Neighboring support operations |

|||

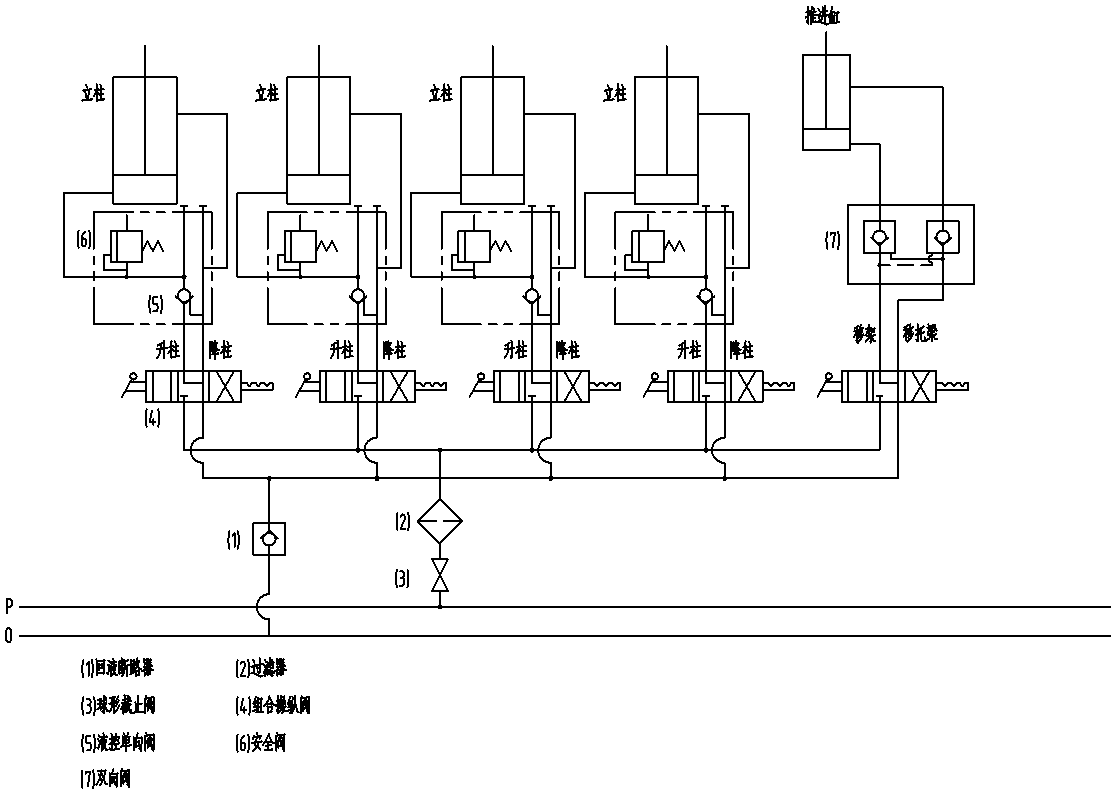

Hydraulic Control System of Cantilever Roof Support